Project Overview

The whole project treatment capacity is 150T/D catering waste, 150T/D kitchen waste and 20T/D waste oil. This treatment system is constructed in the original pre-treatment workshop, along with the construction of a cogeneration workshop, a new 5000mM3 anaerobic fermentation tank, a new 200M3/D wastewater treatment system and an odor treatment system.

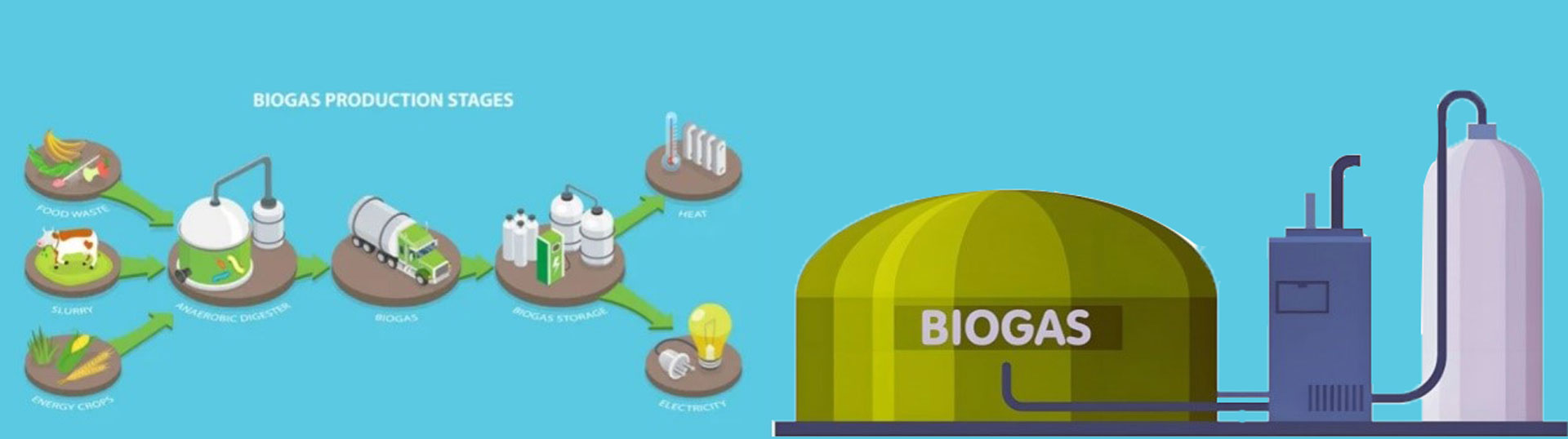

Treatment Process

This project adopts pretreatment+anaerobic fermentation+biogas power generation to treat catering waste, kitchen waste, and waste oil.

The pre-treatment of catering waste adopts material reception+large material sorting+crushing and pulping+sand and impurities removal+oil-water separation.

The pre-treatment of kitchen waste adopts material receiving+tearing and squeezing.

The pre-treatment of waste oil adopts material reception+impurity removal+steaming+three-phase separation)

The pulp generated from the pre-treatment of catering waste, kitchen waste, and waste oil is mixed and anaerobic digested together. The anaerobic generated biogas is first supplied to biogas boilers after purification, and the remaining biogas is used for power generation.

Treatment Capacity

Biogas 12000 NM3/D and 500KW.H/H biogas power supplies