Working Principle

The biogas torch forcibly shortens the flame through the high power air distribution, while the high power air distribution also can forcibly lower the combustion chamber temperature. By low-temperature oxidation reaction, biogas is decomposed and burned, the combustion byproducts are CO2 (carbon dioxide) and H2O (water). Under low-temperature combustion conditions, it can effectively reduce the generation of NOx (nitride) and SOx (sulfide), safely and environmentally.

Technical Features

1. All torch products can be customized based on buyer different standards and needs. We can design the whole sets of biogas treatment equipment and utilization equipment, provide detailed engineering plans and drawings, provide on-site technical guidance for installation, complete equipment debugging and provide technical training and operation instructions.

2. The torch burner uses infinitely variable combustion to achieve the dynamic balance between biogas production and combustion, help to save operating costs.

3. The maximum torch burnout rate of biogas can reach 99.9%, exceeding the highest standard for biogas combustion flue gas emissions and meeting the high standards of large-scale biogas engineering. According to customer customization, ceramic fire-proof modules are used and fire-proof temperature reached 1300°C, effectively isolate thermal radiation and ensure the outside safety of the torch.

4. The torch adopts a PLC control module, with the LCD touch screen display interface. The system can remotely transmit signals. The equipment operation status can be directly observed in the equipment central control room, enabling the control room to start and stop on-site equipment and no need personnel on duty.

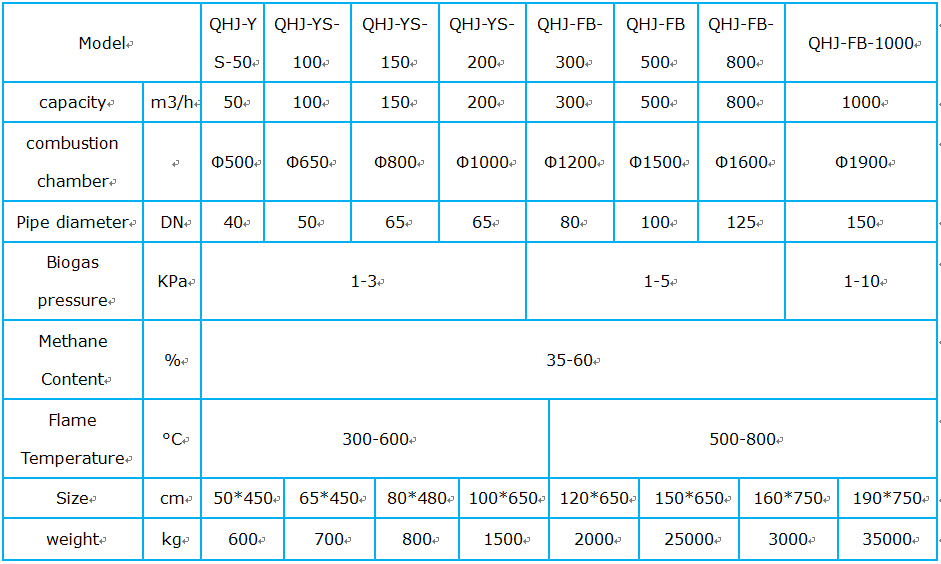

Product Specifications