Working Principle

The process of dry desulfurization is loading certain height of desulfurizer into the desulfurization tower firstly, then biogas through the desulfurizer from bottom to top and H2S is removed. The desulfurizer is commonly used as iron oxide, which is cylindrical in shape. The principle of iron oxide desulfurization is as follows: Fe2O3·H2O+3H2S=Fe2S3·H2O+3H2O

Fe2O3 absorbs H2S and becomes Fe2S3. With the continuous production of biogas, iron oxide absorbs H2S. When the certain amount of H2S is absorbed, the removal rate of H2S will greatly decrease until zero. Fe2S3 can be reduced and regenerated, and can be reduced to Fe2O3 through chemical reactions with O2 and H2O. The principle is as follows: 2Fe2S3·H2O+3O2=2Fe2O3·H2O+6S

Based on the above two reaction equations, Fe2O3 absorbs H2S and then turns into Fe2S3. To reduce Fe2S3 to Fe2O3, O2 and H2O are required. This can be achieved by adding air to the tower or air drying for desulfurization.

Technical Features

1. The dry desulfurization effect is stable and desulfurization efficiency is over 99%.

2. The desulfurization accuracy is and the initial export sulfur content can be reduced to 0.

3. For small flow biogas, the investment cost and operation cost are very low.

4. The whole device has compact structure and small footprint.

5. The device can achieve unmanned, stable, safe and reliable operation.

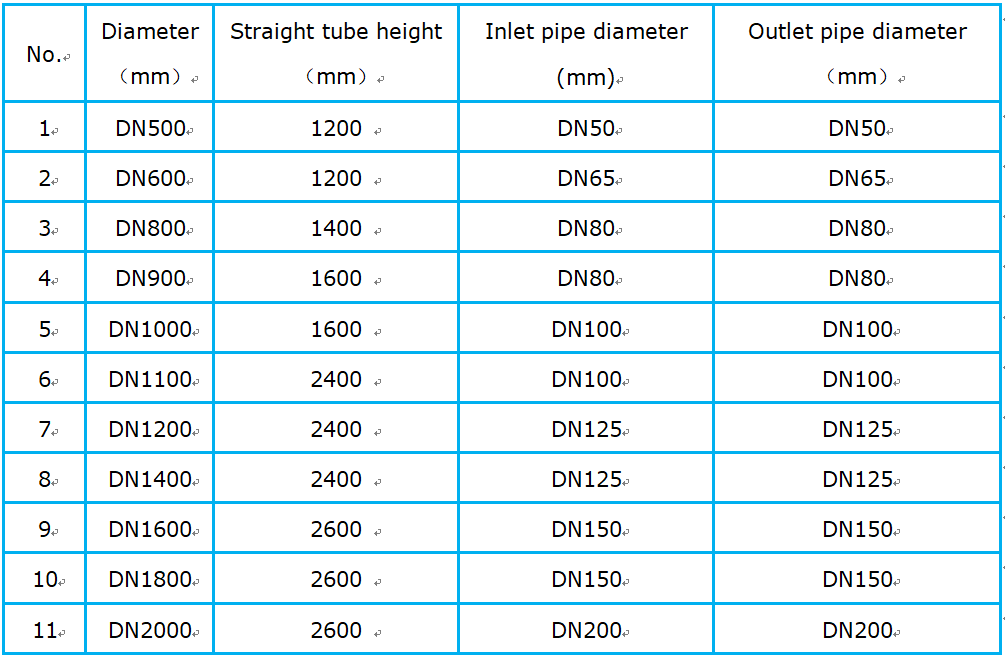

Product Specifications